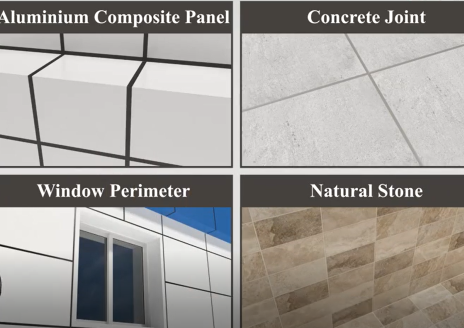

Importance of concrete expansion joints and joint sealant

- Good Environmental Choice Australia (GECA) certified

- ASTM C920 (Class 50) compliant

- ISO 11600 (F Class 25 LM) compliant

- Good UV resistance

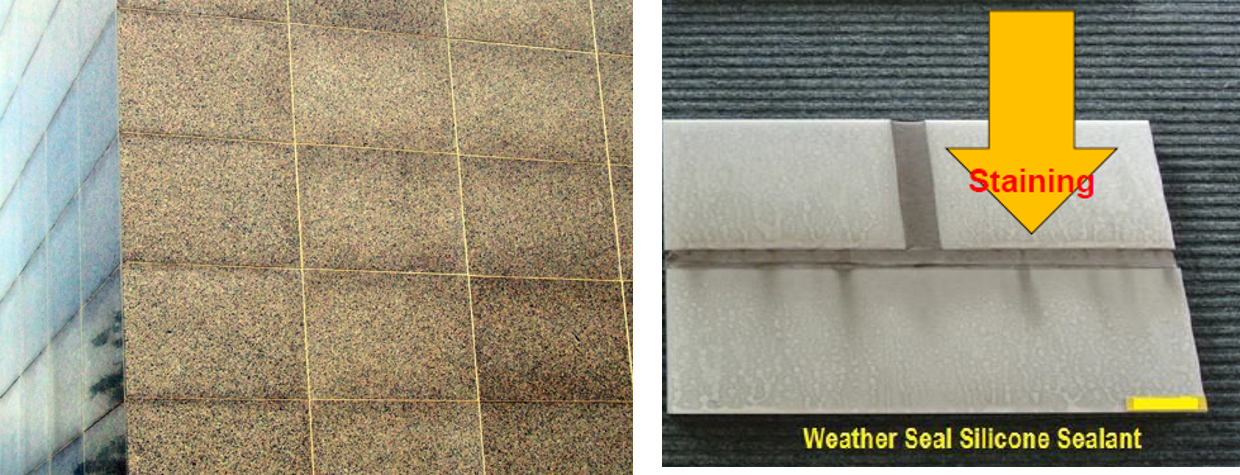

- Low static charge – Less dirt streaking

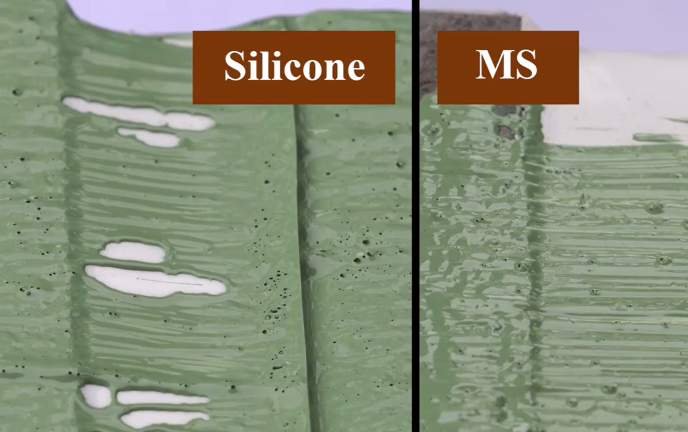

- No silicone oil – Non-staining on adjacent substrates

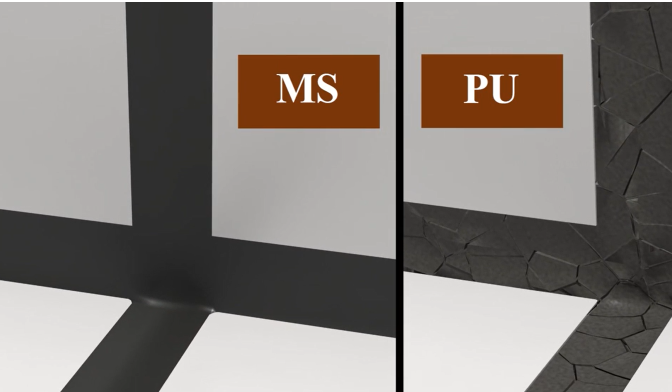

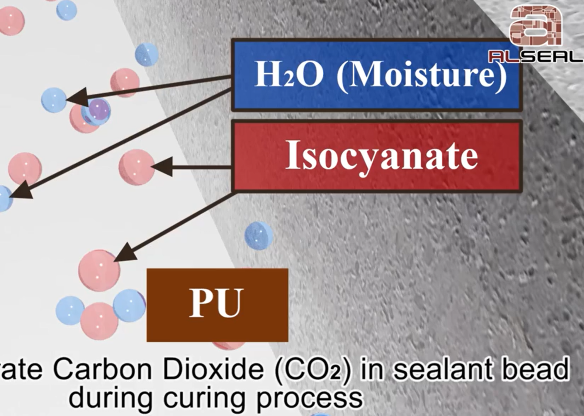

- No isocyanate – No air bubbling

- No solvent – No shrinkage

- Bonds most substrates without primer

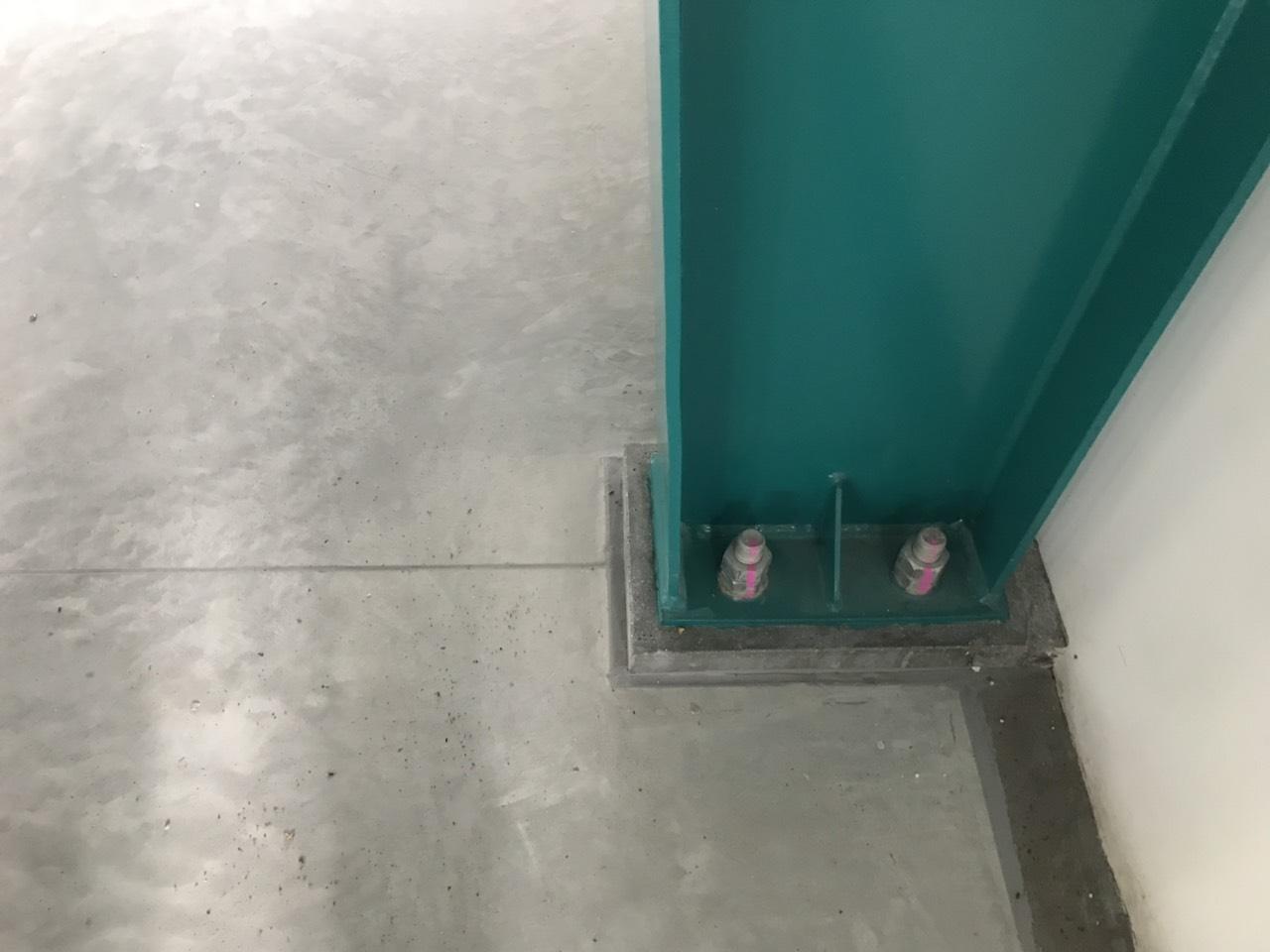

- Place joints around 30 times the slab thickness apart. So, for a slab which is 100mm thick, the joints should be placed around 3,000mm (3 metres) apart.

- Make sure joints are cut deep enough: they need to be at least a quarter of the thickness of the slab. For a 100mm slab, cut the joints at least 25mm deep.

- If you’re cutting joints after the concrete has been poured, don’t leave it too long. Concrete might crack if the joints aren’t cut within 12 hours after finishing.

- Placing joints under walls will mean they won’t be seen.

- Joints are most effective when the aspect ratio of the slab is kept to 1:1, for example 5m x 5m if the slab is a narrower than it is long it is possible to increase this to a maximum aspect ratio of 1.5 for example 2m x 3m, don’t leave the placing of concrete expansion joints to chance and enlist the services of a structural engineer if several are required.

- For a neat sealant edge, it is recommended to use masking tape.

- To better control sealant depth and avoid 3-side bonding, use backer rod.