Bolt and nut corrosion protection by Nitohullmac XG | How it works

Bolt and nut corrosion protection by Nitohullmac XG | How it works

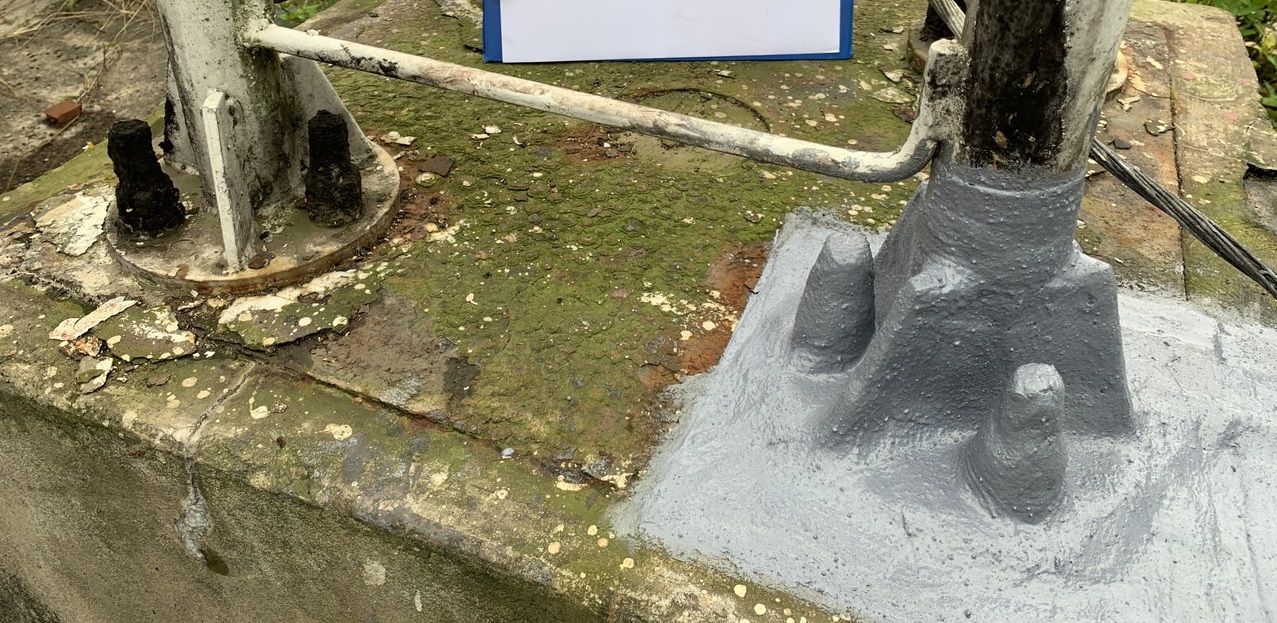

| Functions Protect metal structures such as bolts, nuts, flanges, pole connector plates from corrosion. | Corrosion protection requirements- Encapsulation system that covers all bolts, nuts and flanges in one application and is maintenance free;

- Sprayable organic coating system, polymeric resin based, providing protection for any metallic surface;

- Remove easily (as it does not adhere to the substrate) without the need for special equipment and reusable (recyclable) ;

- Its formula contains corrosion inhibitors that offer equipment maximum protection against contamination and corrosion. The polymeric resin surrounds the metal component providing a passive protection while allowing the oil based corrosion inhibitors to actively protect the substrate and arrest any existing or new corrosion by starving the process of oxygen and preventing moisture/ dust ingress

In harsh chemical factory environment, bolting systems are often the first to corrode. Lets have a look at what mechanisms cause this rapid deterioration and how chemical prone factory operators can protect bolted piping and flanges, and lengthen the service life of coatings.

In harsh chemical factory environment, bolting systems are often the first to corrode. Lets have a look at what mechanisms cause this rapid deterioration and how chemical prone factory operators can protect bolted piping and flanges, and lengthen the service life of coatings.