Frequently Asked Questions: Anti-corrosion Tape NITOHULLMAC XG Series

Is Nitohullmac XG coating system paintable?

Yes, it is paintable using water based paint.

Does it contain inhibitor and create and closed protection system?

Yes, the essence of the product is in its inhibitor, which obsorbs, stabilizes corrosion. The filler, tape and topcoat create a closed system that covers all components to be protected, prevent penetration of corrosive substances such as oxygen, dust, water, vabor, chemicals etc.

How to compute consumption materials?

Please contact us for advice and support.

Can the Product protect those structure/parts that are already corroded?

Definitely, once the Product is wrapped onto the already-corroded steel structures, from the inside, the primer coat will inhibit rust advance by permeating rust layer because it is oil type, and from the outside, the Anti-UV membrane can, with good weatherbility, shut out water and air that will lead to corrosion of metal surface.

Is there any special requirements on surface preparation? is it a must to remove all existing coating?

No. surface preparation is very simple, only requires hand tools: stiff brush and cloth. There is no need to remove all existing paint. The inhibitor primer can penetrate through the coating.

Is the product human and environment friendly?

Yes, it is organic based, safe to human and environment.

What are the issues arising when using ordinary anti-corrosion products?

(1) PVC tape: PVC tape becomes aging, cracking and failure under weather impacts; (2) Petrolatum tape: Grease in tapes melts down under high temperature, dry and cracking under cold weather, fail to protect metal components due to the penetration of corrosive substances onto metal surfacae; corrosion continues development under the cover.

What is its application procedure?

How long is its service life?

Up to 20 years depending on the operating conditions.

How it is packed and what is its consumption rate?

- Inhibitor primer XG-PN: 16kg/set, consumption rate: 300g/m2

- Non-woven fabric XG tape: Size: 1.1mm thick x 100mm/200mm/200mm wide x 10m long

- Mastic filler XG-M: 20kg/set, consumption rate:: ~ 0.93kg/m2

- UV resistant topcoat XG-T: 16kg/can, consumption rate: 300g/m2

How many kind of tapes and its applications?

Nitto Denko manufacturer now offers 2 types of products for outdoor structures, above ground and for underground, underwater .

How long is the shelf life?

18 months from date of manufacture provided that it is stored in dry roofed place under 30oC.

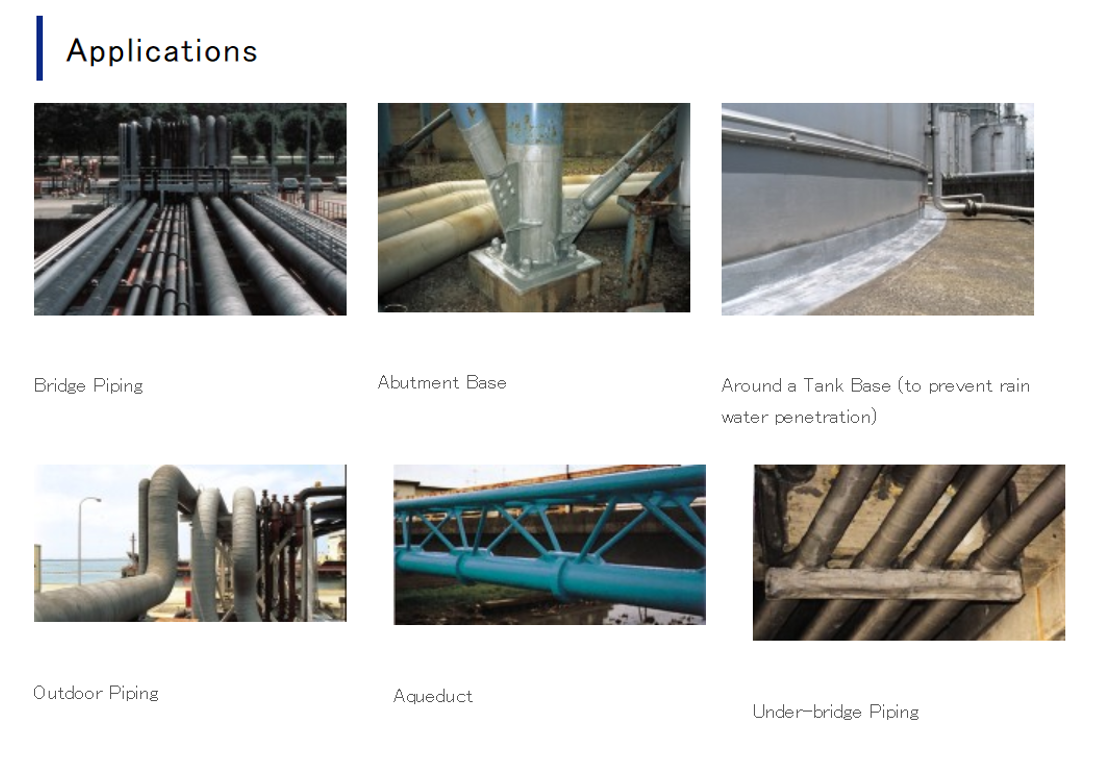

What are the applications of the product?

Nitohullmac XG series is an ideal product for corrosion protection of metal components of complicated shapes (valves, flanges, bolts and other irregular shapes) which are frequently subject to chemical, sea water. It applies to gas pipelines, chemical storage tank base, bolts, valves, flanges, joints in industrial plants, telecom, petroleum, for both new construction and maintenance.

Is the topcoat UV resistant and waterproof?

Yes, the polimer based topcoat, once dry, creates a membrane which can resist UV, waterproof and prevent penetration of corrosive substances onto metal surface.

Does it permit inspection after application, and is it reusable?

Yes. Once applied. the product creates a medium soft closed sealing system which can be opened for regular inspection (of thickess, bolt fixing), then restores to its original state by adding primer and tape. Opened tape can be reused if properly stored, not contaminated.

What is the working temperating range?

minus 50oC to 90oC

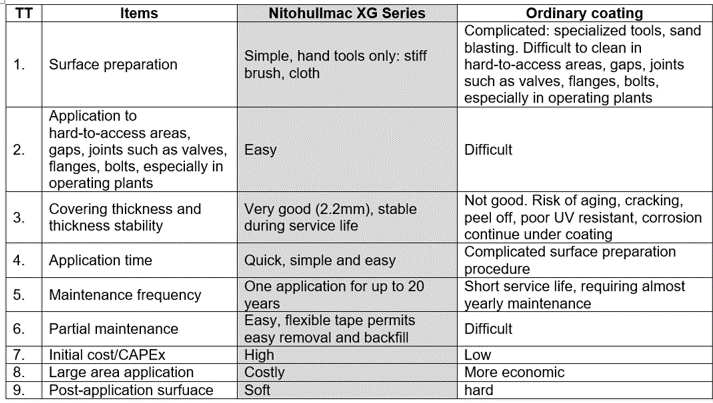

What are its advantages over painting/coating?

Is there any UV resistance and salt spray test results?

See here

How does it work?

- Right on metal component surface, the inhibitor primer inhibits and stabilizes corrosion. Inert organic filler, in addition to its main function of mastic, can transfer primer to the small gaps and hard-to-access areas. It remains stable under high temperature, not melts down at high temperature and not dry under cold weather. Non-woven fabric tape, together with topcoat, create a closed systerm covering the metal components, prevents penetration of water, vabor, and other corrosive substances onto the metal surface.

- Apply once only and maintainance free up to 20 years depending on operating condition. Flexible tape permits easy removal and recycle (in case of opening for regular inspection of component thickness or tightening the bolts). Easy to apply even with irregular shape components, only requires simple cleaning steps.