Importance of concrete expansion joints and joint sealant

What are concrete expansion joints and why are they important?

What is a concrete expansion joint?

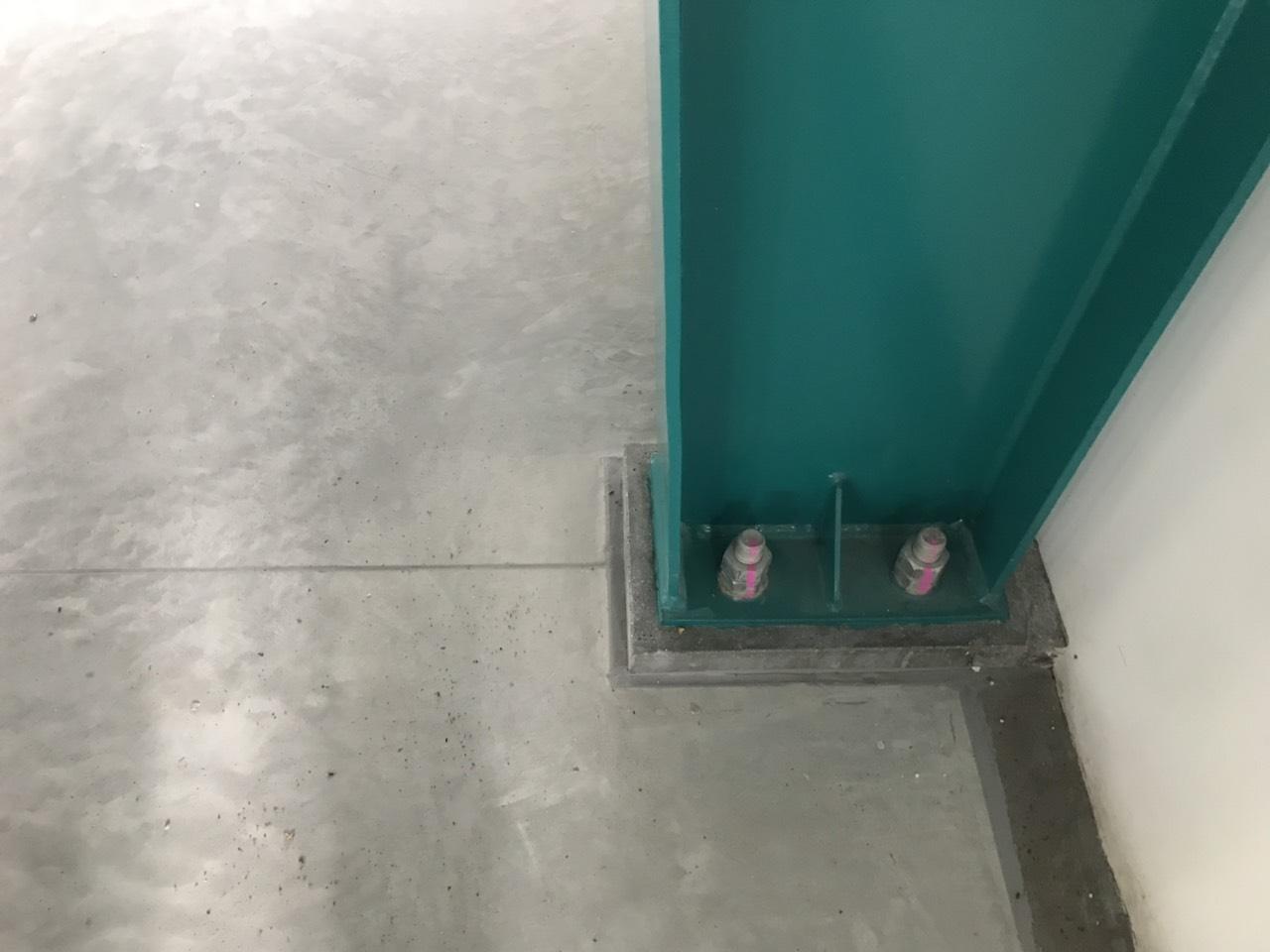

A concrete expansion joint – or control joint – is a gap which allows the concrete to expand and contract as/when the temperature changes. It forms a break between the concrete and other parts of a structure to allow movement without causing stress, which can lead to cracking. They should be used in large concrete slabs such as foundations and concrete driveways.

The expansion joint shall be covered by sealant to prevent dust accumulation, water and secure a smooth drive on the surface. Normally there 2 kinds of sealant used for expansion joint namely polyurethane (PU) and modified silicone (MS sealant) sealant.

PU sealant is often harder to apply, may cause bubbles (as it contains isocyanate), shrinkage (as it contains solven – a kind of gas which evaporates during curing) and less UV resistant than MS sealant. MS Construction Sealant is a one-part, high-performance hybrid sealant that is based on advanced MS Polymer technology. It has excellent weathering, UV and temperature resistance characteristics, and with outstanding features:

- Good Environmental Choice Australia (GECA) certified

- ASTM C920 (Class 50) compliant

- ISO 11600 (F Class 25 LM) compliant

- Good UV resistance

- Low static charge – Less dirt streaking

- No silicone oil – Non-staining on adjacent substrates

- No isocyanate – No air bubbling

- No solvent – No shrinkage

- Bonds most substrates without primer

- Place joints around 30 times the slab thickness apart. So, for a slab which is 100mm thick, the joints should be placed around 3,000mm (3 metres) apart.

- Make sure joints are cut deep enough: they need to be at least a quarter of the thickness of the slab. For a 100mm slab, cut the joints at least 25mm deep.

- If you’re cutting joints after the concrete has been poured, don’t leave it too long. Concrete might crack if the joints aren’t cut within 12 hours after finishing.

- Placing joints under walls will mean they won’t be seen.

- Joints are most effective when the aspect ratio of the slab is kept to 1:1, for example 5m x 5m if the slab is a narrower than it is long it is possible to increase this to a maximum aspect ratio of 1.5 for example 2m x 3m, don’t leave the placing of concrete expansion joints to chance and enlist the services of a structural engineer if several are required.

- For a neat sealant edge, it is recommended to use masking tape.

- To better control sealant depth and avoid 3-side bonding, use backer rod.