Why Sealant Joints Fail: Avoiding Sealant Application Failures

1. Substrate must be clean and dry for the sealant to adhere properly.

Mục lục

- Not cleaning at all

- Using contaminated or dirty solvent

- Using the wrong solvent for a particular sealant,

- Allowing contaminated solvent to dry on the substrate

- Using contaminated rags or brushes

- Using a rag containing lint

2. Improper use of sealant.

The second most common adhesion issue is caused by the improper use of sealant and primers. What does this mean?- Poor quality sealant. Now MS sealant, with innovated technology, can overcome weaknesses of PU and silicon sealant.

- Not using the primer at all

- Using too much primer

- Using the wrong primer for the specific sealant or substrate

- Not allowing the primer to dry completely before adding the sealant

3. Weather on day of application.

Temperature is key.- Cold temperatures causes the sealant to lose viscosity which makes it difficult to apply without gaps and voids and it will be too thick to properly tool. Cold air may retard the cure and if the substrate has contracted due to the temperature then the joint will be wide open. Issues occur when the substrate warms up and expands, causing the joint to close and the sealant to be squeezed out entirely.

- High temperatures can cause the sealant to sag or flow out of the join resulting in failure. Premature skinning over the sealant bead can also occur resulting in craze cracking.

- Dry surfaces are imperative. Dew, frost or any sort of precipitation will guarantee adhesive failure. The same applies if the substrate is still damp from a previous rain.

4. Field applications that can go awry.

- The most common is substitution of the specified product. Many sealants look alike, but they do not perform in the same way.

- Improper storage can cause sealants to freeze, prematurely cure, or exceed their shelf life.

5. Don’t paint your sealant!

- Most paint will not adhere to your sealants and are not formulated nor intended to take the kind and amount of movement to which sealants are subjected.

- If the paint does adhere it will crack when the joint moves.

- If the paint cracks so does the sealant.

6. Joint surface detail.

- The edges of the joint must be smooth and not jagged so the sealant doesn’t develop air pockets during installation.

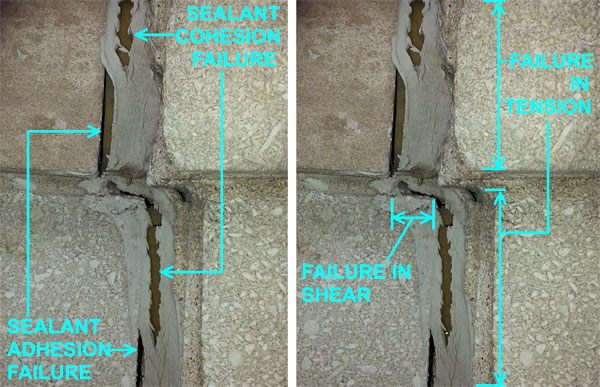

- Any mortar must be removed or cohesive failure can result.

7. Importance of backer rods.

- Backer rods create the proper depth to width ratio, act as a bond breaker, and provide a firm surface for tooling.

- Failure to specify an appropriate bond breaker can cause nightmares.

- A joint with three sided adhesion will fail cohesively, adhesively or both.

- Closed-cell backer rods should not be used with sealants that cure by reacting with moisture in the air. These rods must also be protected from puncturing to avoid outgassing.

- Open cell backer rods should not be used where moisture absorption into the backer rods can be a problem.

- Backer rods are held in place by compression therefore, the rod selection should be about 20% larger than the maximum expected joint opening. If it is too small it will not function as intended and proper tooling will be impossible.

8. Usage of bond breaker tape.

- Bond breaker tape should be used only where there is a firm bottom surface and when the joint is so shallow that a backer rod will not fit.

- Tape sizing is very important. If it is too small, three sided adhesion will result; if it is too large, the tape will wrap around the bottom and sides of the joint, eliminating some of the bonding area required for good adhesion.

9. Benefits of tooling

- Helps protect the weather tightness of the joint by eliminating air pockets created behind the sealant during gunning.

- Forces sealant contact with the side of the joint promoting good adhesion.

- Sealant is pushed against the backer rod and pressed into an hourglass shape allowing it to stretch properly.

- Without tooling, the bond area between the sealant and the sides of the joint may not be sufficient to prevent the sealant from pulling away from the sides of the joint.